Trade fairs

September 18, 2023, Hanover

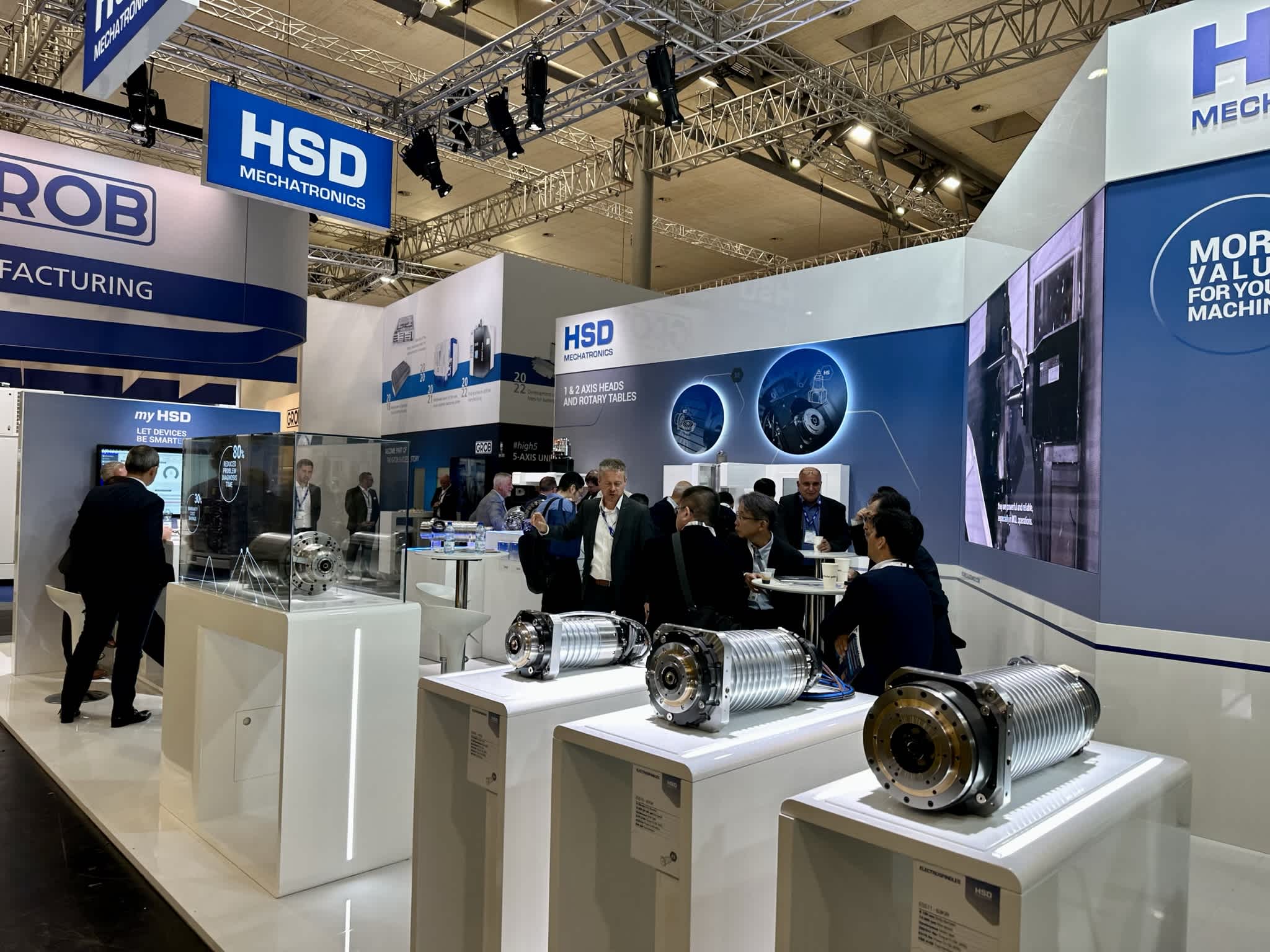

HSD at EMO 2023, the best technology to machine metal on show in Hanover

TRADE FAIRS AND EVENTS

SIMTOS 2024

01 April 2024 / 05 April 2024

CCMT 2024

08 April 2024 / 12 April 2024

BIEMH 2024

03 June 2024 / 07 June 2024

IWF 2024

06 August 2024 / 09 August 2024