THE PERFECT COMBINATION OF MECHANICS AND ELECTRONICS

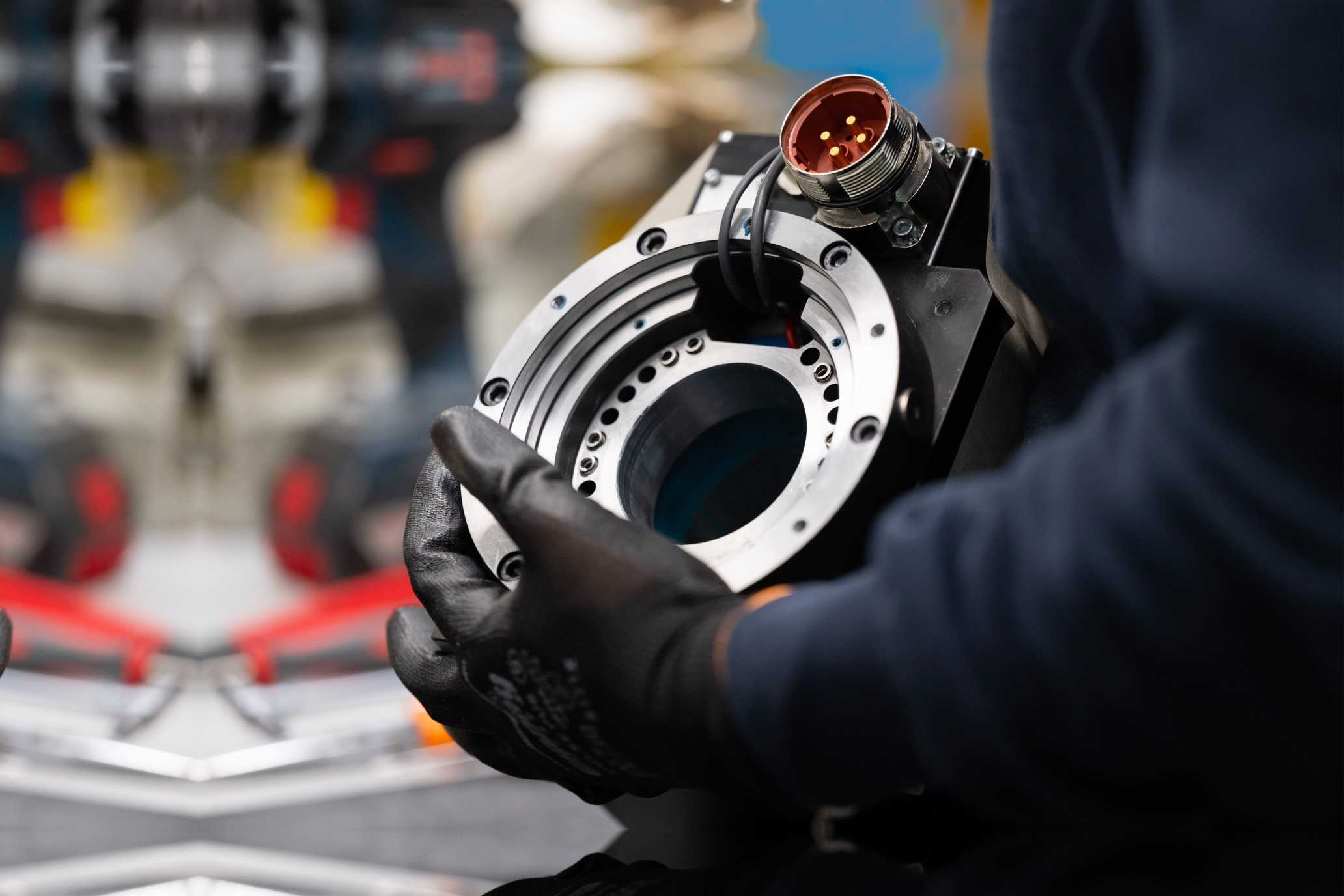

HSD stands out from the crowd thanks to its cutting-edge mechatronic solutions, combined with its uncompromising engineering precision.

Products News

HST610 DS

ES1000

ES1020

ES1000

ES1000

Electrospindles ATC

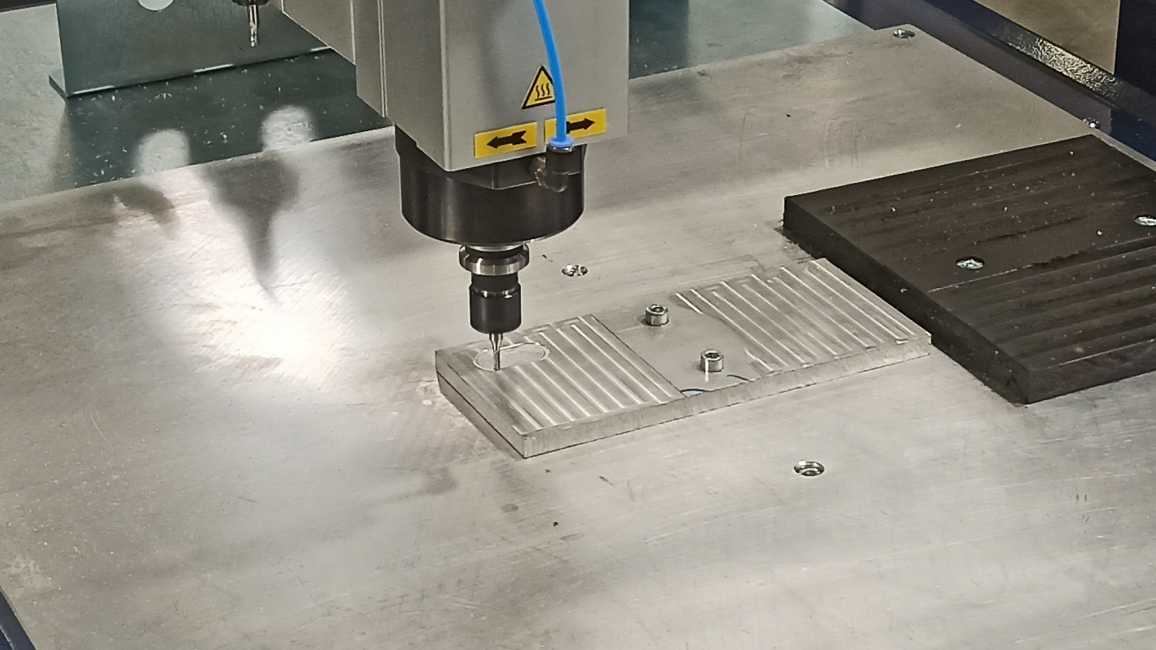

The ES10Line electrospindle range is dedicated to applications on vertical machining centres, for milling and lathe work on metals.

Metal

HOW CAN WE HELP YOU?

Select the topic and describe the information you need. The system will direct your request to the right department, and someone will be in touch with a comprehensive answer as soon as possible.

The fields are mandatory.

SUBSCRIBE TO THE NEWSLETTER

Do you want to stay up-to-date on the world of HSD?

Subscribe to our newsletter now!

NEWS

Events

October 20, 2023, Gradara

Technology, workshops and speed for the first edition of the Discovery Tour in Gradara

Corporate

January 11, 2023, Gradara

HSD China: the new Headquarters in Shanghai

Products

September 18, 2023, Gradara

HSD, a BIG PLUS certified manufacturer

TRADE FAIRS AND EVENTS

SIMTOS 2024

01 April 2024 / 05 April 2024

CCMT 2024

08 April 2024 / 12 April 2024

BIEMH 2024

03 June 2024 / 07 June 2024

IWF 2024

06 August 2024 / 09 August 2024